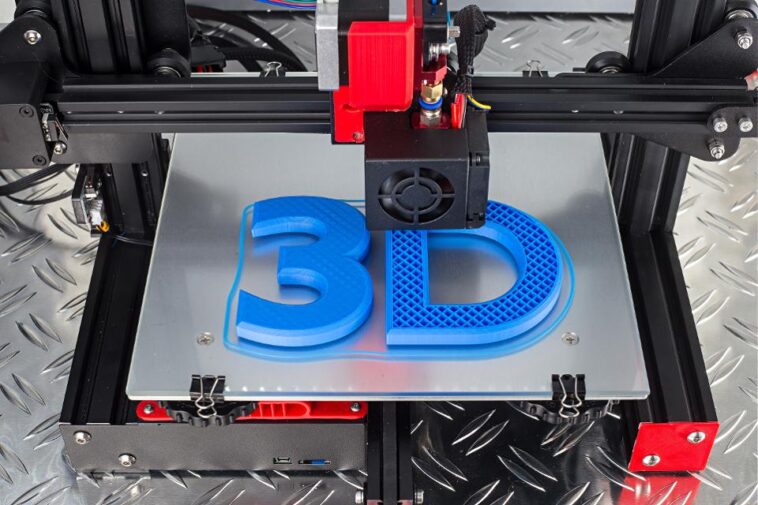

Now you may create an outstanding custom 3D photograph from any photo! Those stylish 3-D personalized photograph frames are beautiful and last for 50 years or extra. Our custom 3D printing manner provides a crisp three-D image that seems to flow in a modern black body. Customized 3D pictures are a unique preference for any occasion. New techniques in the printing era suggest that 3-D printing is less expensive for any domestic now. If you want to save your pictures for a long time, then 3D printing is the best option for you because 3D printing can make your snaps long-lasting. 3D printing is lenticular printing on high-quality 3D puppy sheets in a fascinating modern-day body with your custom photo “floating” in jaw-losing 3-D. Edge band protection intends those heirloom-pleasant photographs are as sharp as they’re cute. 3-d frames are confident for 50 years of indoor use! Water-proof and washable, your memories are extra than safe and unforgettable with our three-D printing era.

Advantages of 3D printing

Much the same as conventional assembling, 3D printing forms each have exceptional qualities and compromises. 3D prints from Pops are the best option for keeping your snaps for a long time. The preferences recorded beneath, in any case, are commonly valid for a wide range of 3D printing. Additive manufacturing is tons easier to supply than conventional machining, regularly through on-line pricing systems like pops platform. With 3D printing, a component’s final results are dictated by means of the selected manner and element parameters. In only a couple of drop-downs, a challenge may be equipped to order without the need for specified engineering prints.

Affordability

The coolest method to remember your best recollections. Select your most loved photographs and transform them into 3D prints! The size we as a whole love, in 3D. For each is and traditional manufacturing, the overall value of element effects from both fabric expenses and machining time. However, with 3D printing, there aren’t any fees related to devising setup and finishing as in conventional production. For subtractive production, these consist of cloth procurement, programming tool paths, configuring a setup, going for walks and tracking the device, and any completing work like deburring or sanding. With injection molding, those costs are even more of an element because of pricey tooling required before any parts can be made. none of these fees are present with am, resulting in appreciably cheaper elements.

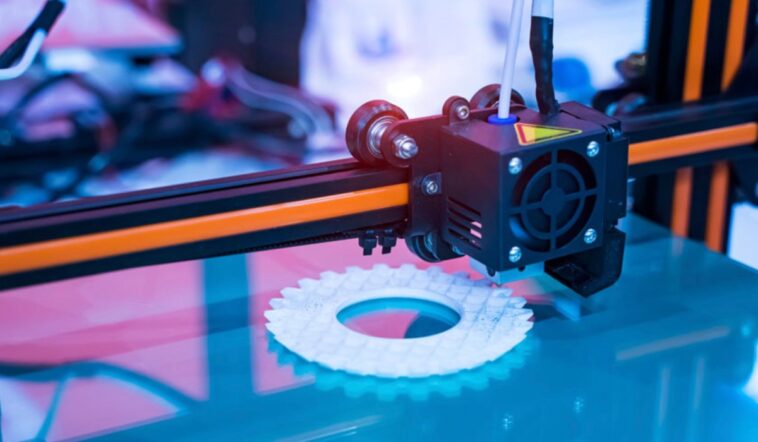

Speed

After platform set-up, most elements may be manufactured in much less than an afternoon. Every so often, part production may even take much less than an hour. The agility of 3D printing is basically because of its simplified setup, which most effective calls for build training software programs in place of a machine setup required by traditional machining. 3-D printers can produce a couple of elements with more than one configuration, regularly in a single build, and with no additional setup fees. For example, mini yours custom designed lets customers create customized car trim and different functions through 3-D printing. With conventional procedures, this would require high-fee tooling in keeping with the layout. The ability to selectively configure parts, blended with three-D printing, allows businesses to target finer customer segments with customized merchandise.

Read More on the fastest 3D printers in the market right now.

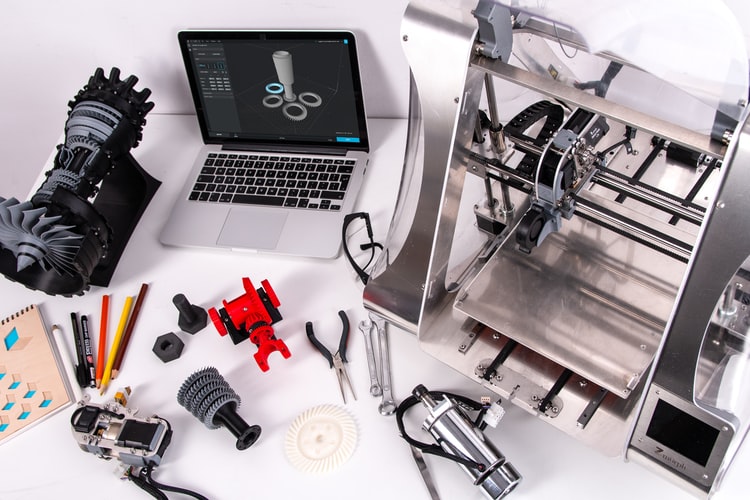

Purpose-driven designs

While designing for traditional production, the dressmaker ought to make concessions for manufacturability and price reduction. Functional functions regularly want to be adjusted to allow for production. The “most effective” layout is frequently not possible to manufacture with conventional means. With am, this is not the case. in reality, many new layout possibilities exist for making all-in-one, topology-optimized, and lightweight components through additive manufacturing. 3-D printing allows ideas to expand quicker than ever. being able to 3-D print an idea the identical day it was designed shrinks an improvement manner from what might have been months to a remember of days, supporting groups live one step beforehand of the competition.

Snapshot prototyping and design validation

With the decreased time to manufacture and less stringent layout restrictions, am allows designers to swiftly design and iterate on their prototypes. With traditional manufacturing, it can take weeks to get a physical prototype for your arms. with am, you may frequently have a component in hand within the week. This lets in designers and engineers to test and exchange their thoughts on the fly. Ultimately, a new product pass to manufacturing a whole lot faster. An excellent analogy is transferring from movies to virtual cameras. inside the beyond, you had 24 shots on the digital camera and you will be extra selective on if and when to take pix. With digital, you may take thousands of photos with almost no fee and ultimately can help you pick the excellent out of these alternatives, ensuing in a better product.

Build your Imagination

Inside the current increase of digital artwork and design, the possibilities are not handiest accelerating but infinite. One could now 3-D print almost anything they believe after drawing it up truly. In an incredibly quick time, a concept, idea, dream, or invention can cross from a simple notion to a produced component that you could preserve. With fashionable mass-production, all elements come off the assembly line or out of the mold the same. With 3D printing, you can actually customize, personalize and tweak a component to uniquely fit their desires, which allows for custom fits within the clinical and dental industries and facilitates set humans apart in the fashion and jewelry global.