Semiconductor manufacturing is a highly intricate and demanding process, and at the heart of it lies the crucial step of testing. Semiconductor testing ensures that the chips produced meet the highest quality standards. However, it comes with its own set of challenges, from handling delicate wafers to maintaining precision equipment. In this blog post, we will delve into the world of semiconductor testing and explore tips for achieving streamlined efficiency in this critical stage of production.

Introduction to Semiconductor Testing Challenges

An essential step in the creation of integrated circuits is semiconductor testing. It entails a series of tests to gauge the chips’ dependability and functionality. Testing semiconductors presents a variety of difficulties. The first is the sheer complexity of the chips, which is getting more and more sophisticated with each new technological development. Second, the examination must be precise and accurate since even small mistakes can result in expensive flaws. The constant drive to cut manufacturing costs and time to market is the final factor.

For further information on semiconductor testing and to explore cutting-edge solutions, you can visit https://www.silybwafers.com/

Importance of Efficient Test Wafer Procedures

Efficient test wafer procedures are the backbone of streamlined semiconductor testing. They play a pivotal role in reducing production costs, minimizing examination time, and ensuring the reliability of test results. By optimizing these procedures, semiconductor manufacturers can achieve significant competitive advantages.

Shorter testing times translate to faster time-to-market, a critical factor in a rapidly evolving industry. Efficient test wafer procedures also lead to cost savings by reducing material wastage and resource utilization. Moreover, they enhance the overall quality of semiconductor products by minimizing the potential for contamination and human errors during the process.

The importance of efficient test wafer procedures cannot be overstated. They are instrumental in driving efficiency, improving product quality, and ultimately contributing to the success and competitiveness of semiconductor manufacturers in a highly demanding market.

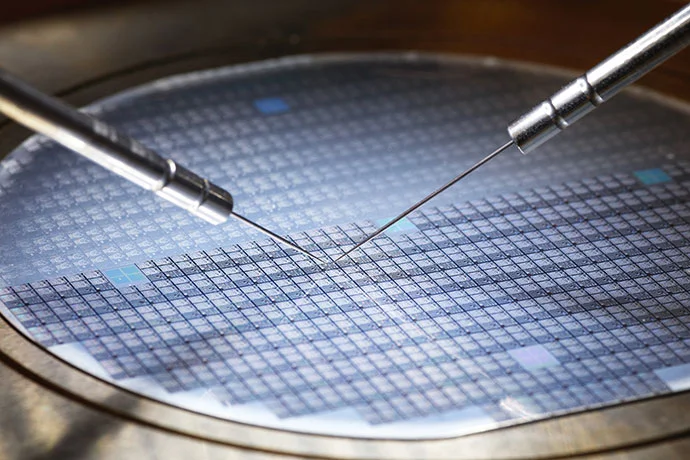

Selecting the Right Test Wafers for Your Needs

The choice of test wafers is a critical factor in semiconductor testing efficiency. Different applications and testing requirements demand specific types of wafers. Silicon wafers, for instance, are widely used due to their availability and compatibility with various processes. However, specialized applications may require alternative materials, such as gallium arsenide or silicon carbide. It is imperative to select the right wafer material, size, and thickness to align with your examination objectives.

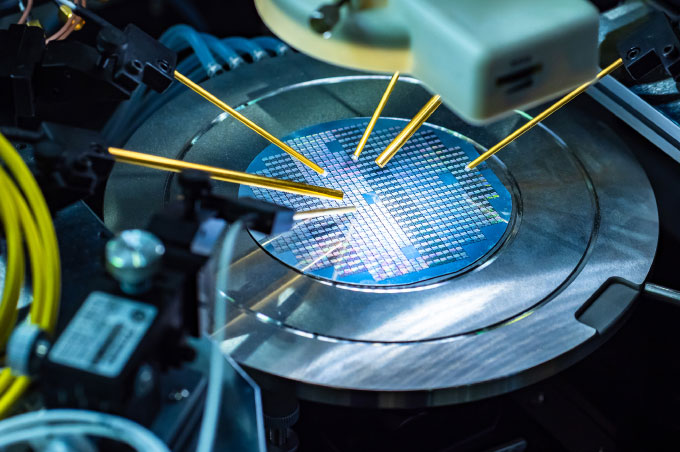

Streamlining Wafer Handling and Preparation

Efficient wafer handling and preparation are key to reducing testing time and minimizing contamination risks. Implementing cleanroom protocols and automation systems can significantly improve the handling process. Moreover, investing in advanced equipment, like wafer aligners and inspection tools, can enhance wafer preparation accuracy, ultimately leading to more reliable test results.

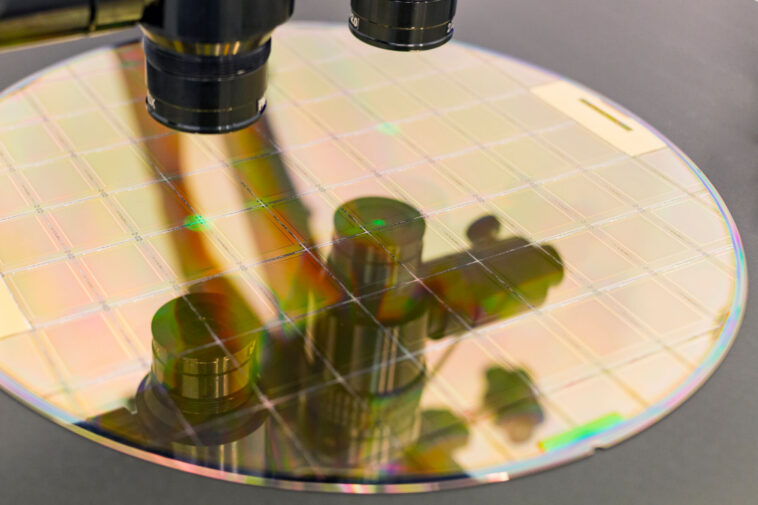

Optimizing Test Equipment Setup and Calibration

Proper setup and calibration of test equipment are paramount for accurate testing. Regular maintenance and calibration routines should be established to ensure equipment reliability. Automated calibration procedures can streamline this process, reducing downtime and enhancing examination efficiency. Additionally, keeping spare parts readily available can prevent unexpected delays due to equipment breakdowns.

Implementing Automated Testing Processes

Implementing automated testing processes revolutionizes semiconductor testing. Automation enhances throughput, reduces human errors, and ensures consistency. Robotic handlers, coupled with automatic test equipment (ATE) and wafer mapping systems, create a seamless workflow. They enable round-the-clock testing, optimizing production capacity.

Automation also enhances repeatability and reproducibility, critical for achieving consistent results in semiconductor examination. With precise control and data collection capabilities, automated systems can detect deviations and anomalies quickly, allowing for immediate corrective actions. This not only boosts efficiency but also improves the overall quality of the tested chips.

In today’s fast-paced semiconductor industry, where time-to-market is crucial, automated testing processes are a strategic advantage. They empower manufacturers to meet demands efficiently, maintain competitiveness, and stay at the forefront of technological innovation.

Data Management for Streamlined Analysis

Efficient data management is crucial for extracting meaningful insights from the vast amount of test data generated during semiconductor testing. Advanced data analysis tools and databases should be employed to organize, store, and analyze this data. Real-time monitoring and data visualization can help identify trends and anomalies quickly, enabling proactive decision-making and process improvements.

Reducing Downtime with Preventive Maintenance

Downtime can be a major productivity killer in semiconductor testing facilities. To minimize downtime, manufacturers should implement a proactive preventive maintenance program. Regularly scheduled maintenance checks and equipment inspections can identify and address potential issues before they cause disruptions. This approach not only reduces downtime but also extends the lifespan of expensive equipment.

Collaborating with Suppliers for Better Results

Collaborating with suppliers is a strategic move that can yield remarkable results in semiconductor manufacturing. Suppliers are valuable partners in the journey towards greater efficiency and quality. They bring expertise in materials, equipment, and processes that can directly impact the final product.

By working closely with suppliers, semiconductor manufacturers can access the latest advancements in wafer materials, equipment, and calibration techniques. This collaboration helps ensure a reliable supply chain, reducing the risk of delays or shortages. Moreover, suppliers often offer insights and support that can lead to cost reductions and performance improvements.

In a rapidly evolving industry, collaboration with suppliers fosters innovation and flexibility, enabling semiconductor manufacturers to adapt to changing demands and technologies. It is a symbiotic relationship that enhances competitiveness and positions companies for sustained success.

Training and Skill Development for the Team

Efficient practices are not just about technology; they also depend on the skills and knowledge of the workforce. Continuous training and skill development programs should be in place to keep the team updated on the latest industry trends and technologies. Well-trained technicians and engineers are better equipped to troubleshoot issues, operate equipment efficiently, and adapt to evolving requirements.

Conclusion

Semiconductor testing is a critical stage in chip production, and achieving efficiency in this process is paramount. By selecting the right test wafers, streamlining wafer handling, optimizing equipment setup, implementing automation, managing data effectively, reducing downtime through preventive maintenance, collaborating with suppliers, and investing in team training, semiconductor manufacturers can reap a host of benefits. These benefits include faster time-to-market, reduced production costs, improved product quality, and a competitive edge in the ever-evolving semiconductor industry.

Efficient testing practices not only impact the bottom line but also contribute to the overall advancement of semiconductor technology. As manufacturers adopt these streamlined approaches, they will be better positioned to meet the growing demand for smaller, faster, and more powerful chips that power our digital world.